Western Red Cedar Feather Edge Cladding

Canadian Western Red Cedar Feather Edge Cladding has very few knots and a mixture of colours. It is extremely durable.

Photo: Treated Western Red Cedar Feather Edge

Work out a Price Below

1) Click to choose a Feather Edge Cladding profile

2) Click to choose a grade of Western Red Cedar

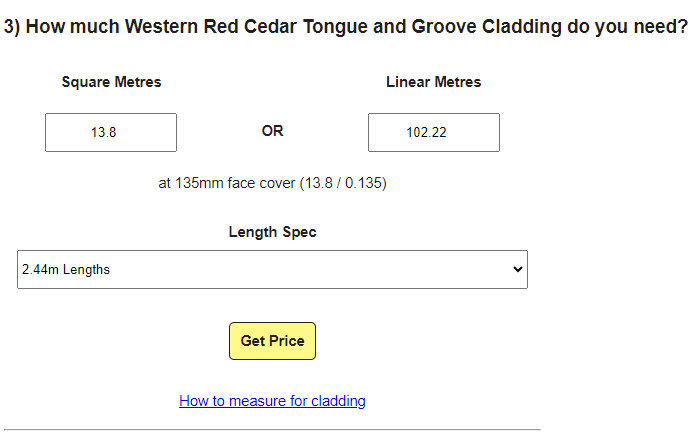

3) How much Western Red Cedar Feather Edge Cladding do you need?

Related Products

Western Red Cedar Feather Edge Cladding

Western Red Cedar Feather Edge Cladding is provided in two profiles:

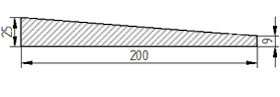

- IWC9 - 200mm wide Feather Edge Cedar Cladding - to be overlapped 25mm giving 175mm face cover

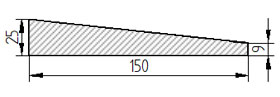

- IWC10 - 150mm wide Feather Edge Cedar Cladding - to be overlapped 25mm giving 125mm face cover

These profiles are to be fitted horizontally and overlap each other. If you would like a custom profile, then please send through the drawing for the profile and we will get that quoted for you separately.

As opposed to our other forms of cladding, feather edge is a sawn product rather than machined and are more flexible at the time of fitting because you get to choose how much overlap you would like. This is a much more traditional product than our other forms of cladding and is a great cost-effective alternative.

Western Red Cedar is a deep reddish brown and is almost instantly recognisable. The clear and better grade that we supply it in adds to its aesthetically please nature because it contains minimal knots making it a clean and fresh-looking timber.

Western Red Cedar feather edge cladding doesn’t require treatment like other timbers because the boards are subject to minimal movement.

We supply Western Red Cedar Feather Edged Cladding in lengths of 2.13m and longer. We usually provide random lengths to cover the area you specify, if you do need exact lengths please contact us on 01889 279 018 or jump on the chat to make sure that the lengths you need are available before ordering. If they are, there is a “Special Instructions” box on our shopping basket page where you can type the lengths you need so that we know when processing your order.

Sawn featheredge Cedar wood cladding isn't the only cladding option we offer, we can also supply machined profiles such as Tongue and Groove and Planed All Round.

Treatments

Most people leave their timber to go the traditional silver-grey in the sun. We recommend talking to www.wood-finishes-direct.com if you would like to treat your timber. If you do decide to treat your timber, it needs to be treated all the way round including the ends to prevent moisture getting in at all.

Canadian and British Western Red Cedar

Please see below some pictures of planed all round Western Red Cedar slats. Although they aren't pictures of cladding you will be able to see the colour difference between the Canadian and British Western Red Cedar which will help you to make a choice between the two.

Canadian Cedar

British Cedar

- David Le Versha

A strong relationship exists between iWood and The Bespoke Kitchen and Interiors Ltd. The reasons are simple and constant. The product and delivery from iWood has been first class. There has been good flexibility in the size of each delivery which has enabled stock levels to be carefully controlled. Wastage has been kept to a minimum because iWood delivers exactly what is promised. This is a company that really understands us. Thanks for listening and responding so well to a small company.

- Richard Edmondson

I'm very happy with the customer service here and will be definitely using iWood again in the future.

- James Marshall

Stanbrook & Nicholson Ltd have been buying European Oak from iWood since their inception. In our trade it is often difficult to get both service and product quality from our suppliers. iWood have consistently provided us with an absolute first rate product with service to match. A high proportion of our timber purchased comes as cut to size putting our wastage at nearly zero per cent. This also speeds our process of manufacture.

- Ben Stanbrook and Simon Nicholson

Just a quick line to say thanks for the swift delivery of the ash I ordered a couple of weeks ago. It is now installed as stair treads/ landing and looks superb. Just one small gripe, the delivery driver didn't call me to say he was on his way which meant I had to rush over; he did help me carry it into the house though. I think the picture does them justice.

- Stephen Barker, Spalding

Clear & Better No.2

Product Code: IW-18-24-44-3

Specify: Clear & Better No.2 Cedar, Western Red External Cladding Feather Edge Cladding from iWood Timber

DELIVERY TIMES

Our timber is imported straight from sawmills on the continent. Our usual lead times are therefore 10 to 14 working days.

WHAT ARE YOUR DELIVERY COSTS?

We calculate our delivery costs based on how far away you are from us, to get more information on this please check out our shipping costs page.

DELIVERY DAY

Our delivery lorries visit different parts of the country on different days, so once your order is ready we will work with you to arrange a delivery day for when one of our lorries is in your area. We will always arrange the delivery day in advance with you.

DELIVERY TIMES

We deliver weekdays Monday to Friday between the hours of 8am to 5pm. Our delivery vehicles will have multiple jobs on them which can affect the delivery time to you, depending on factors such as traffic and how long it takes to offload the previous jobs. The driver will call you in advance with an estimated time of arrival to make sure you'll be there.

HOW DO I PLACE AN ORDER FOR CLADDING?

You can place your order online by working out your price above and adding your items to your shopping basket. You can then check out and your order will be processed securely and a confirmation email sent. Once your order arrives in our depot, we'll give you a call to arrange delivery.

CAN I ORDER SAMPLES?

Yes you can, you can order samples of certain timbers at www.iwood.co.uk/sample-request/. If the species you need isn't there please give us a call or talk to us on our online chat.

The timbers shown are planed all round samples and are not profiled.

Call our seasoned sales team on 01889 597 281.

Send us a message through our Contact Form.

Email your cutting list to enquiries@iwood.co.uk.

Main Menu

Main Menu

Added to Basket

Added to Basket